Toolox® 33

General Product Description

The pre-hardened, exceptionally clean tool and engineering steel.

Thanks to its low carbon and alloy content, Toolox® 33 is perfectly adaptable for welding as well as hot cutting. Giving the possibility to product components more cost efficient by saving machining time.

Dimension Range

Toolox 33 is available as plates in thicknesses between 6.0 – 130.0 mm. Other dimensions can be available on request.

Mechanical Properties

| Thickness (mm) | S Hardness (HBW) | Yield strength Rp0.2 (min MPa) | Tensile strength Rm (min MPa) | Elongation A5 (min %) |

|---|---|---|---|---|

| 6.0 – 130.0 | 275 – 325 | 700 | 800 | 10 |

Hardness is measured, according to EN ISO 6506-1, on a milled surface 0.5 – 2 mm below the plate surface.

Impact Properties

| Thickness (mm) | Min impact energy for transversal testing, Charpy V 10×10 mm test specimen |

|---|---|

| 6.0 – 130.0 | 35 J / 20 °C |

Ultrasonic testing

Ultrasonic inspection is carried out according to : EN 10 160 with extra demands according to specification .

Tolerances

More details are given in brochure Toolox® Guarantees and on www.toolox.com.

Thickness

Toolox® Guarantees meets the requirements of EN 10029 Class C but offers more narrow tolerances.

Length and Width

Tolerances according to EN 10029.

Flatness

Tolerances are according to Toolox® Flatness Guarantees, which are more restrictive than EN 10029 Class N (steel type L).

Surface Properties

According to EN 10163-2 Class B, Subclass 3.

Delivery Conditions

Quenched and Tempered at a minimum temperature of 590 °C.

On delivery the plates meet the following specifications:

- Free from mill scale

- Not repair welded

Delivery requirements can be found in brochure Toolox Guarantees or at www.toolox.com.

Fabrication and Other Recommendations

Welding, bending and machining

For information concerning welding and fabrication, see brochures on consult Tech Support.

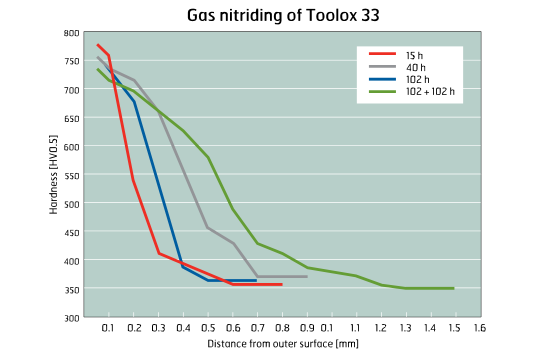

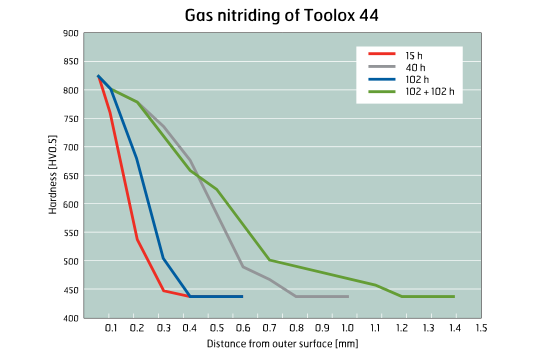

Toolox® products is not intended for further heat treatment. If Toolox is heated above 590 °C after delivery no guarantees for the properties of the steel are given. Nitriding or surface coating may be carried out if the temperature is below 590 °C.

Appropriate health and safety precautions must be taken when welding, cutting, grinding or otherwise working on the product. Grinding, especially of primer coated plates, may produce dust with high particle concentration.

Contact Information

Toolox® 44 round bars

General Product Description

Pre-hardened, precise, predictable steel, now in round bars.

Toolox® round bars are pre-hardened, ready-to-use quenched and tempered tool steels that come in a wide range of diameters from small to large.

Suitable for engineering applications in tool holders and in different types of shafts and rolls, the diameter dimensions also provide a better solution for round parts in tooling applications like molding and in dies for aluminium die casting.

Dimension Range

Toolox 44 round bars is available in diameters 21.0 – 282.0 mm. Other dimensions can be available on request.

Mechanical Properties

| Diameter (mm) | Hardness (HBW) |

|---|---|

| 21.0 – 282.0 | 410 – 475 |

Hardness is measured, according to EN ISO 6506-1, on a milled surface 0.5 – 2 mm below the plate surface. Bar hardness is measured on a milled surface, with indents positioned as impact test according to EN 10 083.

Impact Properties

| Diameter (mm) | Hardness (HBW)Min. impact energy for longitudinal testing, Charpy V 10×10 mm test specimen |

|---|---|

| 21.0 – 141.0 | 410 – 475 |

Impact testing according to EN 10 083.

Ultrasonic Testing

Ultrasonic inspection is carried out according to : EN 10 160 with extra demands according to specification.

Tolerances

Tolerances for Toolox® round bars are according to EN 10 060.

For more information concerning dimensions and tolerances, see Toolox® round bars dimensional program: Toolox® engineering & tool steel dimensional program bars or Toolox® Guarantees available at www.toolox.com.

Delivery Conditions

Quenched and Tempered at a minimum temperature of 590 °C.

On delivery the round bars meet the following specifications:

- Free from mill scale

- Not repair welded

Delivery requirements can be found in brochure Toolox® Guarantees or at www.toolox.com.

Fabrication and Other Recommendations

Welding, bending and machining

For information concerning welding and fabrication, see brochures on consult Tech Support.

Toolox® products is not intended for further heat treatment. If Toolox is heated above 590 °C after delivery no guarantees for the properties of the steel are given. Nitriding or surface coating may be carried out if the temperature is below 590 °C.

Appropriate health and safety precautions must be taken when welding, cutting, grinding or otherwise working on the product. Grinding, especially of primer coated plates, may produce dust with high particle concentration.

Contact Information

TOOLOX READY TO USE ENGINEERING &

Typical Values

| Toolox 33 – Mechanical Properties | +20oC | +200oC | +300oC | +400oC | +500oC |

|---|---|---|---|---|---|

| Hardness (HBW) | 300 | ||||

| Hardness (HRC) | ~29 | ||||

| Yield strength Rp0.2 (MPa) | 850 | 690 | 680 | 590 | 560 |

| Tensile strength R (MPa) | 980 | 900 | |||

| Elongation, A5, (%) | 16 | 12 | |||

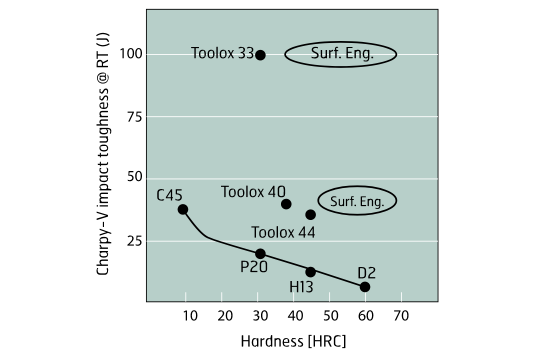

| Impact toughness, Charpy-V (J) | 100 | 170 | 180 | 180 |

| Toolox 40 – Mechanical Properties | +20oC | +200oC | +300oC | +400oC | +500oC |

|---|---|---|---|---|---|

| Hardness (HBW) | 400 | ||||

| Hardness (HRC) | ~40 | ||||

| Yield strength Rp0.2 (MPa) | 1150 | 1010 | 990 | 900 | 780 |

| Tensile strength Rm (MPa) | 1260 | 1170 | 1160 | 1060 | 900 |

| Elongation, A5, (%) | 14 | 14 | 14 | 15 | 16 |

| Impact toughness, Charpy-V (J) | 38 |

| Toolox 44 – Mechanical Properties | +20oC | +200oC | +300oC | +400oC | +500oC |

|---|---|---|---|---|---|

| Hardness (HBW) | 450 | ||||

| Hardness (HRC) | ~45 | ||||

| Yield strength Rp0.2 (MPa) | 1300 | 1150 | 1120 | 1060 | 930 |

| Tensile strength Rm (MPa) | 1450 | 1380 | |||

| Elongation, A5, (%) | 13 | 10 | |||

| Impact toughness, Charpy-V (J) | 30 | 60 | 80 | 80 |

| Physical Properties | +20oC | +200oC | +400oC | |||

|---|---|---|---|---|---|---|

| Toolox 33 | Toolox 44 | Toolox 33 | Toolox 44 | Toolox 33 | Toolox 44 | |

| Heat conductivity (W/m*K) | 35 | 34 | 35 | 32 | 30 | 31 |

| Thermal expansion coefficient (10-6/K) | 13.1 | 13.5 | 13.1 | 13.5 | 13.1 | 13.5 |

| Inclusions | |||

|---|---|---|---|

| Toolox 33 | Toolox 40 | Toolox 44 | |

| Inclusion size (equiv. diam.) | 6 micron | 6 micron | 6 micron |

| Area fraction | 0.015% | 0.015% | 0.015% |

| Aspect Ratio | 1.2% | 1.2% | 1.2% |

| Chemical Composition | Toolox 33 | Toolox 40 | Toolox 44 |

|---|---|---|---|

| C | 0.22-0.24% | 0.28% | 0.32% |

| Hardness (HRC) | ~29 | ||

| Yield strength Rp0.2 (MPa) | 850 | 690 | 680 |

| Tensile strength R (MPa) | 980 | 900 | |

| Elongation, A5, (%) | 16 | 12 | |

| Impact toughness, Charpy-V (J) | 100 | 170 | 180 |

SURFACE TECHNOLOGY

HARD & TOUGH